|Hotline:

+84353287368 |

English

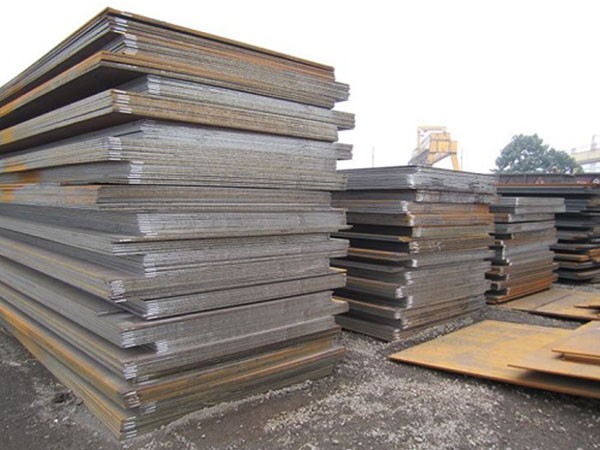

S50C STEEL

S50C STEEL

Chi tiết sản phẩm- Chemical Composition

|

Standard |

Chemical Composition Rate ( Wt, % ) |

||||||

|

C |

Si |

Mn |

Ni |

Cr |

P |

S |

|

|

S50C |

0.47 |

0.15 |

0.6 |

|

|

|

|

|

0.53 |

0.35 |

0.9 |

0.2 |

0.2 |

0.03 |

0.035 |

|

- Physical properties

|

Steel |

Tensile strengh |

Yield strengh |

Relative Elongation |

|

N/mm2 |

N/mm2 |

(%) |

|

|

S50C |

590~705 |

355~540 |

15 |

- Heat treament Process

|

Steel |

Annealing |

Quenching |

Tempering |

Hardness HRC |

||

|

Temperature (°C) |

Temperature |

Oil |

Temperature |

Air |

||

|

(°C) |

(°C) |

|||||

|

S45C |

~600 |

800~850 |

180~200 |

40~50 |

||

4. Apllications

- Making some details in the engine, normal mold, mold base, support plate, gasket mold...

- Used in machine building because of its high heat resistance, good surface resistance, used for rollers, rollers, swingarms, agricultural machinery, and details subject to large loads.....